Process Description

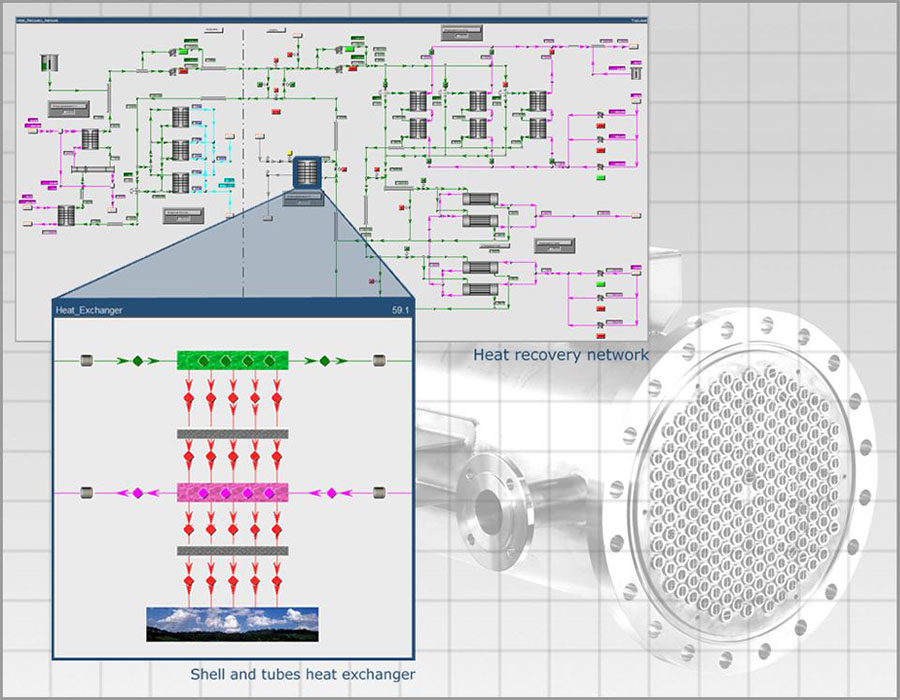

This heat recovery network consists basically of an interconnection of several heat exchangers. There is a heat exchange between one main close loop and five open loops. The network can operate also with a “two close loops” configuration by opening and closing a set of valves.

The equipment of this process are shell and tubes heat exchangers, condensers, pumps, pipeline, valves and controllers.

The equipment of this process are shell and tubes heat exchangers, condensers, pumps, pipeline, valves and controllers.

Objective

Build a dynamic model of the entire heat recovery network, including equipment, pipeline, monitoring displays, controllers and valves. Since the network was under construction the model should predict accurately the performance of the entire network. Pressure drop, heat exchange and temperature profile were of great importance in this model.

Outcome

The model created by Mobatec fulfills all the requirements specified above, and it was used as the principle tool for the process evaluation.

The large distance (> 600m) between the two process parts was a big challenge for the controller tuning and, in some respect, also for the modeling.

The large distance (> 600m) between the two process parts was a big challenge for the controller tuning and, in some respect, also for the modeling.