Take control of Your plants Field Operations.

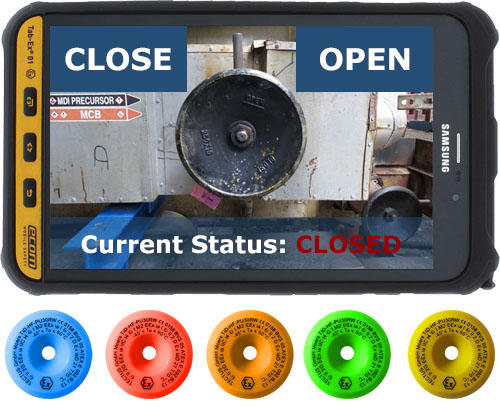

MobaTAGnology is a simple, low cost and multipurpose solution which communicates the status of manual operated devices (e.g. the position of a hand valve) to a Control Room.

|

Industry Problem

An average sized plant has 10.000 hand valves with no feedback to the control system. Making operation mistakes due to wrong or unknown valve positions can result in:

|

|

|

Our Solution

MobaTAGnology provides an overview of actual hand valve positions in the control room (wireless and without use of batteries). This reduces errors in operation, increases speed of actions and makes production safer.

The same Tags can be used to train and certify field operators such that smooth operation is always guaranteed. With them field operators can train together with control room operators or independently on a simulator of any brand. |

|

No Special Infrastructures

No antennas, poles or wires are needed. Just small plastic tags that are stuck or hanged on valves which are scanned with an ATEX handheld mobile phone.

|

|

Low Cost

The order of magnitude of the cost is (much) less than one day of production loss. The return of investment can be expected in a very short period of time.

|

|

Multipurpose

One Smart Tag can serve many purposes depending on the mode of operation. It can be either used for Operator Training or as an Actual position indicator.

|

|

No wiring or batteries

Everything works wirelessly and without batteries. No complications with wires or charging batteries, the user simply scans a smart tag with a handheld device and information is passed over 4G network.

|

|

Intrinsically Safe

Every bit of hardware is ATEX certified so it is intrinsically safe and can be used in explosive atmospheres.

|

|

Simple Hardware

One PC, Tags and a handheld, that’s it.

|

|

Easily Scalable

If it’s just a couple of tags or hundreds the system doesn’t change. In case of scaling the system to many tags no extra hardware is required except for the tags.

|

|

Compatible

The TAGs work with virtualy any Distributed Control System (if it is part of the system) and with any existing Operator Training Simulator.

|

|

No Maintenance

Except for replacing a TAG when it’s lost or somehow broken no maintenance of system is required by the end user.

|