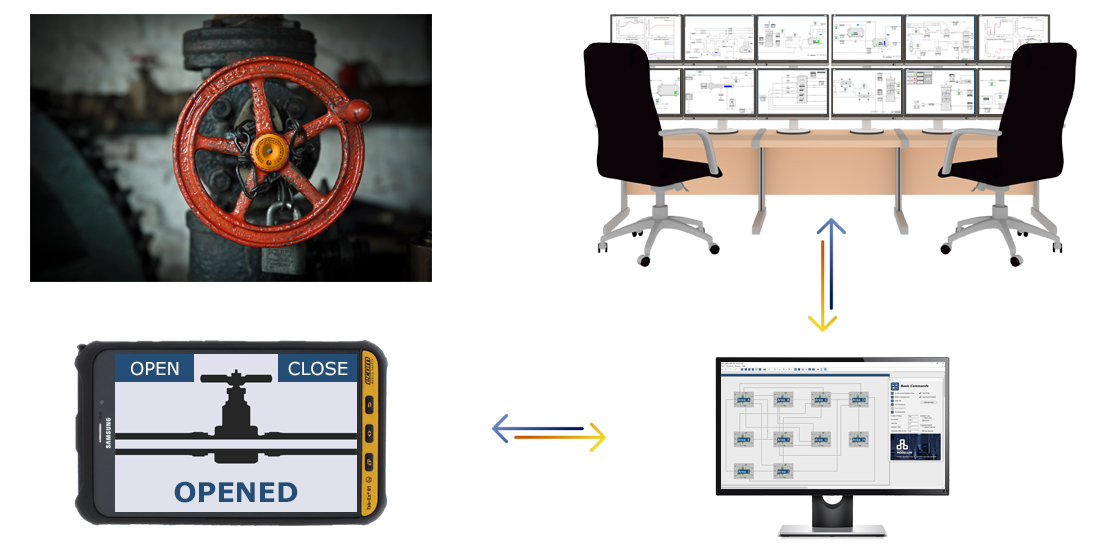

To include field operators in operator training we make use of the real plant (rather than expensive 3D virtual worlds and non intuitive panels) without disturbing the real process. Field Operators scan a Tag with an ATEX Device, after which they can receive and manipulate values at the OTS.

| Field Operators which are involved in training carry handheld ATEX devices and have to walk real distances to perform actions and communicate with the control room with actual ambient noise. This makes the training as close as possible to real life operations. | Actions are immediately visible on the OTS. If for any reason field operators are not available for training, the traditional approach remains possible (where the instructor takes on the role of the field operator). And if for some reason panel operators are not available the field operators can practice line ups with the instructor. |

|

The Field Operator Module of Mobatec can be easily coupled to any existing Operator Training Simulator (vendor independent).

The investment cost of involving field operators in training with an operator training simulator is roughly 20% of the costs of a HiFi operator training simulator of the plant. The leverage: for an additional 20% three times as many operators can be trained (assuming the amount of field operators is twice of that of control room operators). More importantly: the whole crew/shift will be trained, needed to cope with abnormal situations and incidents but also for rare standard operations as start-up and shut down. The order of magnitude of the cost is (much) less than one day of production loss. |

|